Protecting the public when working at height

Contact the appropriate highway authority before

erecting a scaffold on a public highway or on any roads, pavements, paths or routes used by the public.

Ensure the scaffold is designed to carry the load from

stored materials and equipment.

Scaffolds should be designed to prevent materials

falling.You may need to provide brickguards, netting or

sheeting.Where the risk is high, or for example during

demolition or facade cleaning, you should provide extra protection in the form of scaffold fans or covered walkways.

In populated areas such as town centres, erecting and

dismantling scaffolds should preferably be undertaken during quiet times. People should be prevented, with suitable barriers and signs, from walking under the scaffold during erection or dismantling.

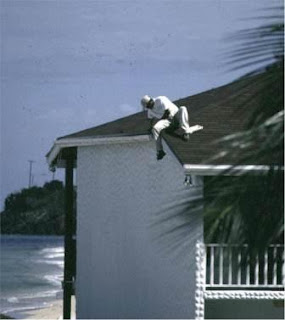

Stop unauthorised access onto the scaffold, for

example by removing all ladders at ground level, whenever it is left unattended.

Never ‘bomb’ materials from a scaffold. Use mechanical hoists or rubbish chutes to move materials and waste.

Design for Safety

To facilitate the design for safety for buildings and structures, a Design Review Process is recommended. It

is a systematic process where the risks of the design are highlighted, reviewed and recorded.

In a Design Review Process, a safety and health review committee is established and should consist of the

main stakeholders such as client, design engineer, architect, project safety and health coordinator and

contractor.

The outcome of the review process should be a safe design endorsed by all parties and a record of the

resultant hazards or vital safety and health information. A GUIDE process is recommended to assist in the

review process.

G – Group together a review team consisting of major stakeholders.

U – Understand the full design concept by looking at the drawings and calculations, or have the

designers elaborate on the design.

I – Identify the risks that arise as a result of the design or construction method. The risks should

be recorded and analysed to see if they can be eliminated by changing the design.

D – Design around the risks identified to eliminate or to mitigate the risks.

E – Enter all the information including all vital design change information affecting